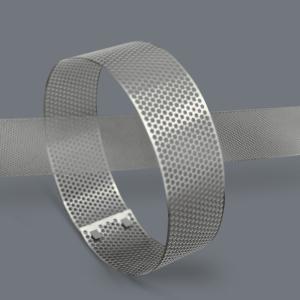

High Precision acid etching typical metal Shims, Washers & Gaskets

Components

Typical Shims, Washers & Gaskets Components

- Flat, memory springs

- Damping shims

- Washers

- Head gaskets

- Sealing shims

Metal Grades For Shims, Washers & Gaskets

- Stainless Steel

- Aluminium

- Titanium

- Nickel Alloys

- Copper

- Nitinol

Key Facts About Shims, Washers & Gaskets

1.Flat Or Assembled

They can be flat, formed or assembled for a variety of technical

applications, including aerospace, F1 & precision engineering.

2.Burr-Free

All are burr-free with no rough edges that could interfere with

mating parts.

3.Digital Tooling

Digital tooling is used to give flexibility in the complexity of

the design, lower cost and speedy delivery.

4.3D Formed Components

3D formed or lipped gaskets can be produced in-house. In addition,

a range of surface finishing is available, including

electroplating, electropolishing and passivation.

Benefits Of The Etching Process

- Low set-up costs and fast lead times make chemical etching a go-to

process in batch sizes of one to multiple millions.

- The tooling for etching is digital, low-cost and can be modified

quickly.

- No heat or force is used when etching so mechanical properties

remain unaltered and parts are free from stresses and burrs.

- As component features are etched at the same time, part/feature

complexity is not an issue.

The chemical etching process is adept at manufacturing a diverse

range of metal components, including

1.Electronic Components: Such as connector contacts, lead frames,

shielding, and various microelectronic parts requiring precise

patterns and high conductivity.

2.Medical Devices: Components for surgical instruments, implantable

devices, and diagnostic equipment, where intricate and

biocompatible parts are essential.

3.Aerospace Parts: Critical components like heat exchangers, shims,

and fuel cell plates, requiring lightweight materials and complex

designs.

4.Automotive Parts: Precision parts like gaskets, meshes, sensors,

and electrical contacts, where durability and accuracy are

paramount.

5.Decorative and Functional Items: From jewelry and decorative

elements to precise mechanical components used in various

industries.

In summary, chemical etching stands as a versatile and precise

manufacturing process that offers a multitude of benefits. Its

ability to produce intricate designs, maintain material integrity,

and facilitate cost-effective production makes it an ideal method

for manufacturing high-precision metal components used across

industries like electronics, aerospace, automotive, medical, and

decorative arts.

Custom Metal Shims

Precision metal shims from 0.010mm-2.5mm thick supplied fast to

your design.

We manufacture a wide variety of custom metal shims, spacers and

thin washer shims which can be supplied flat or formed to your

design specification.

WHAT ARE METAL SHIMS?

Precision metal shims serve as spacers between mechanical

components, effectively absorbing impact, minimising “play” or

movement and safeguarding material surfaces in advanced high-tech

applications. They are commonly produced from diverse metal types,

such as stainless steel, aluminium, brass or copper.

Our benifits

- Save time and money

Our assembly line approach reduces manufacturing time and allows us

to save time by cutting unnecessary steps out of the manufacturing

process.

- Dedicated Team

We have a dedicated team of fully qualified professionals who are

on hand to deal with and complete assembly work requests from our

customers.

- Bespoke Packaging

We offer assembly, soldering and spot welding, bespoke packaging,

and also many other specialist bespoke customer requirements that

our clients may have.

Contact us

Ready to discuss your component design? Share your details for

technical review and pricing.

Email us susan@xinhsen.com

Whats'app +8617879687698